Leading the market

Leading the market

Our products

We provide you with high-quality products, purchase consultation, customized the use environment for you, until the door-to-door design of product parts for you. Let you focus on the development of new products, so that your enterprise development is full of power.

Service market

Service market

Value

We provide you with high-quality products, make full and reasonable use of existing investment, make scientific decisions on future development measures, reduce the R & D cost of enterprises, and maximize the benefits.

Strive to develop

Strive to develop

Team

Our development engineers are experienced. Your demand is our task, your call is our clarion call.

Product Overview

Choose Your ProductFor more detailed product pictures, please refer to the main product column, or contact us for customized solutions and technical supporting services. Customer satisfaction is our biggest service tenet.

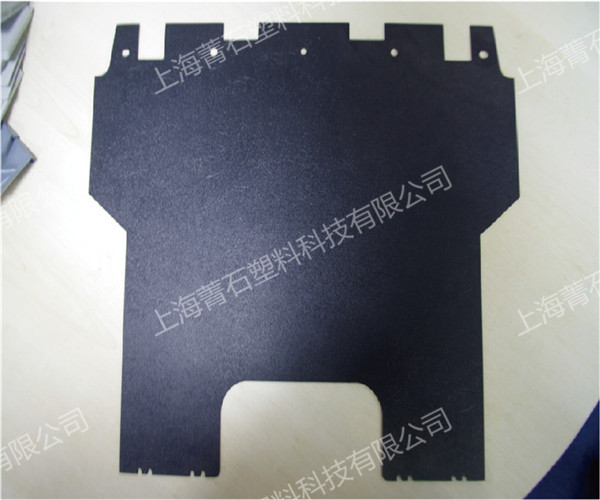

Automobile flame retardant board

Flame retardant panels for car seats

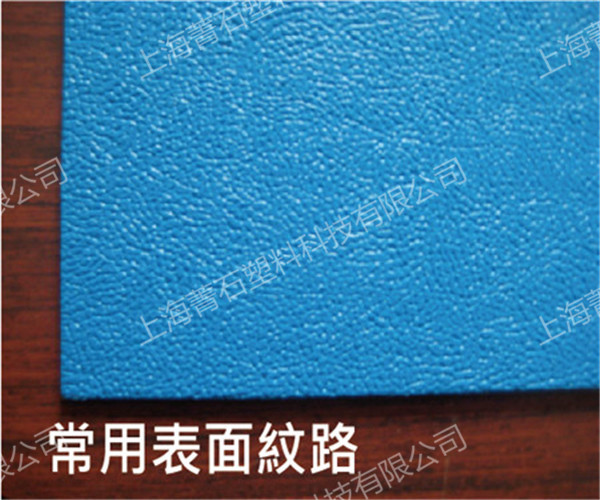

Ground protection

non-slip surface

Stair protection

Wall protection

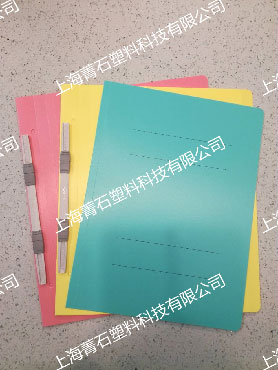

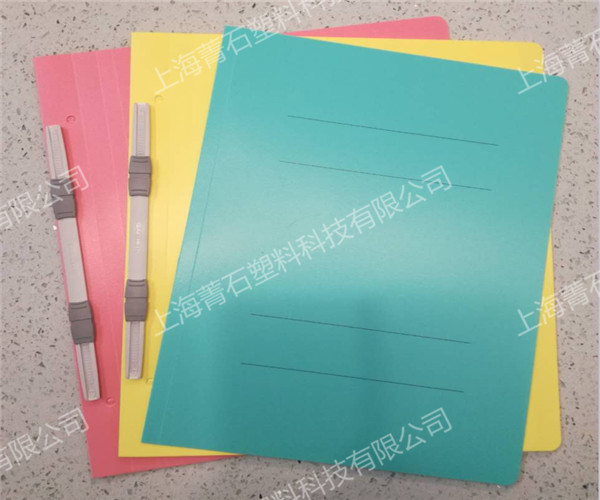

Office Supplies

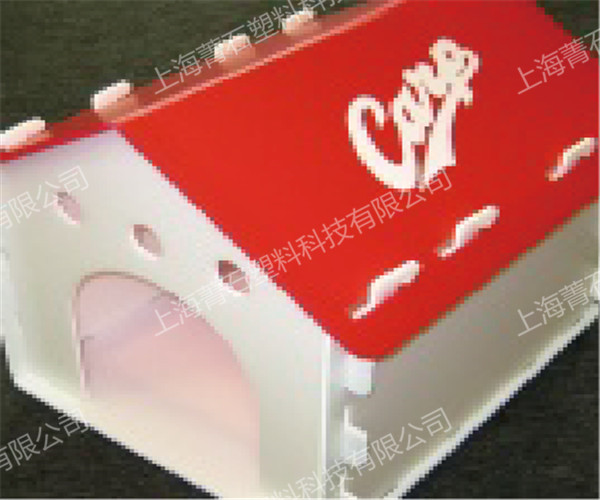

Pet supplies

optical device

Billboard

Toys

luggage and bags

SPS Iron material

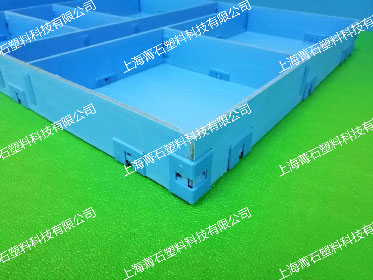

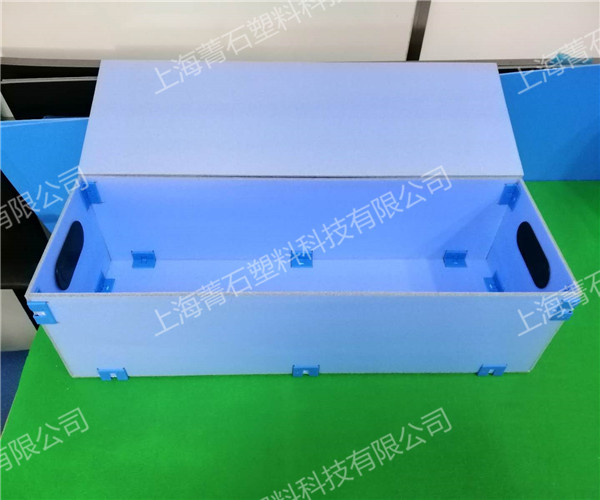

Box assembled by connecting buckle

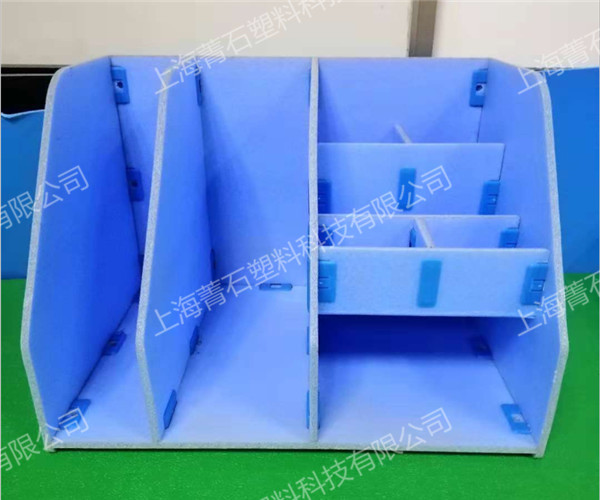

Material shelf

Plastic partition of surface composite EPE

Signboard

hoarding of Circulation Box

Office Supplies

Super light and high rigidity structural foaming PP board

Logo shim

Foaming imitation gypsum board

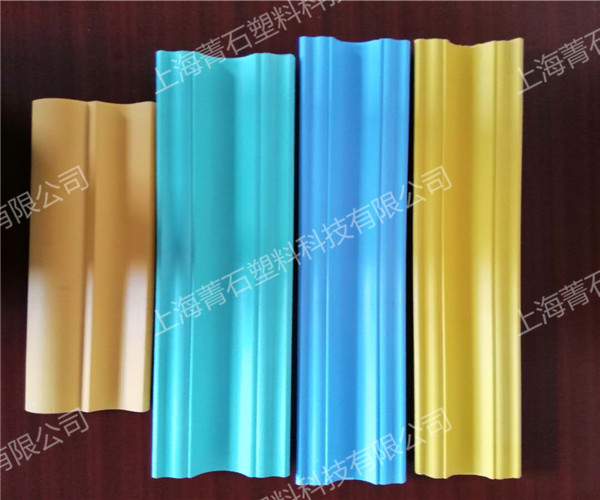

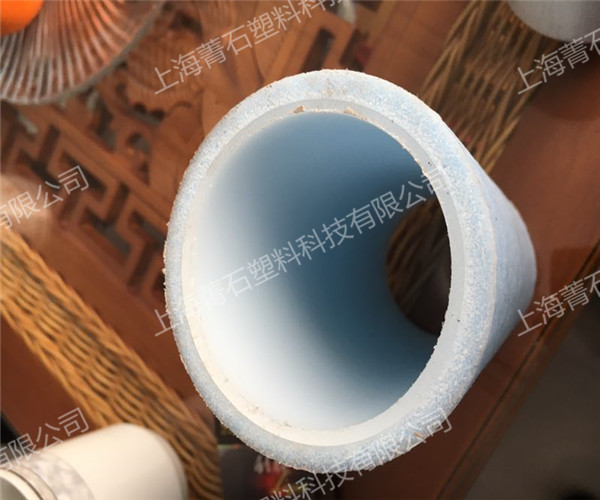

foaming rod

foaming tube

Transparent TSPP film

Transparent cosmetic bag

Transparent zipper bag

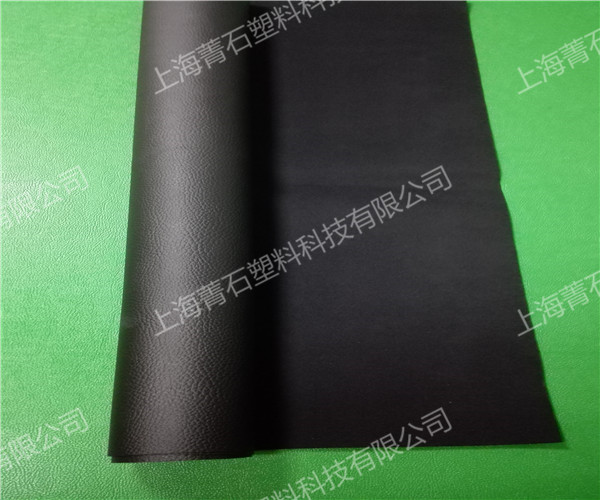

Soft TPO leather

Soft TPO leather

Soft TPO leather

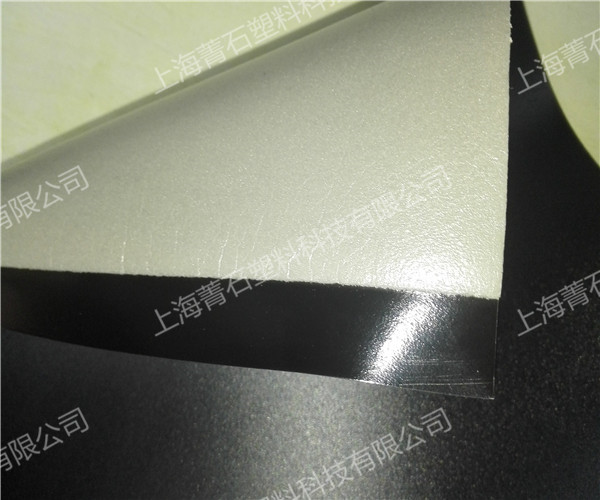

Soft scratch resistant EVA film

Product development

Customized composite materials for aviation and high-speed rail transportation in 2019In the new year. We will continue to strive to provide high-strength and lightweight composite materials for the field of intelligent and lightweight machine artificial intelligence.

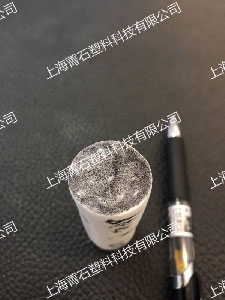

PP foam board

Hot News On The SpotVPP foam board, also known as polypropylene (PP) foam board, is made of polypropylene (PP) as the raw material and foamed with carbon dioxide gas

Brief introduction of PP foam board

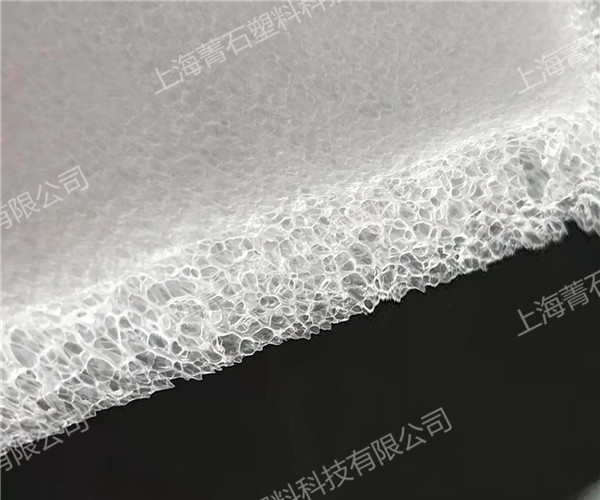

PP foam board, also known as polypropylene (PP) foam board, is made of polypropylene (PP) by carbon dioxide gas. Its density is controlled in 0.10-0.70 g / cm3, thickness is 1 mm-20 mm. It has excellent thermal stability (the maximum use temperature is 120%) and dimensional stability of products under high temperature, suitable and smooth surface, excellent microwave adaptability, degradability and excellent processability.

Properties of PP foam board

Excellent heat resistance. Foamed PS is usually used at 80 ℃, foamed PE can only withstand 70-80 ℃, while foamed PP can withstand 120 ℃. Its compressive strength is lower than that of hard PUR and foamed PS, but higher than that of Soft PUR. Remarkable heat insulation, good resilience, and high impact energy absorption.

PP foam board application

The use of foamed PP is very extensive. It has been applied from small to large to the hull. Foamed PP can play an important role in packaging, automobile, high-speed railway, aerospace, construction and other fields by its excellent heat resistance, sanitation, heat insulation and good environmental effect.